Rang Dong makes safe glass refill for vacuum flasks

Rang Dong’s glass refill comes from strictly controlled production lines and complies with the international standards for food safety, BS EN 12546-1:2000 and LFGB. Customers around the world have been convinced and trusted its perfect glass liner. This article will introduce you the way we make a perfect glass liner for your favorite vacuum flasks.

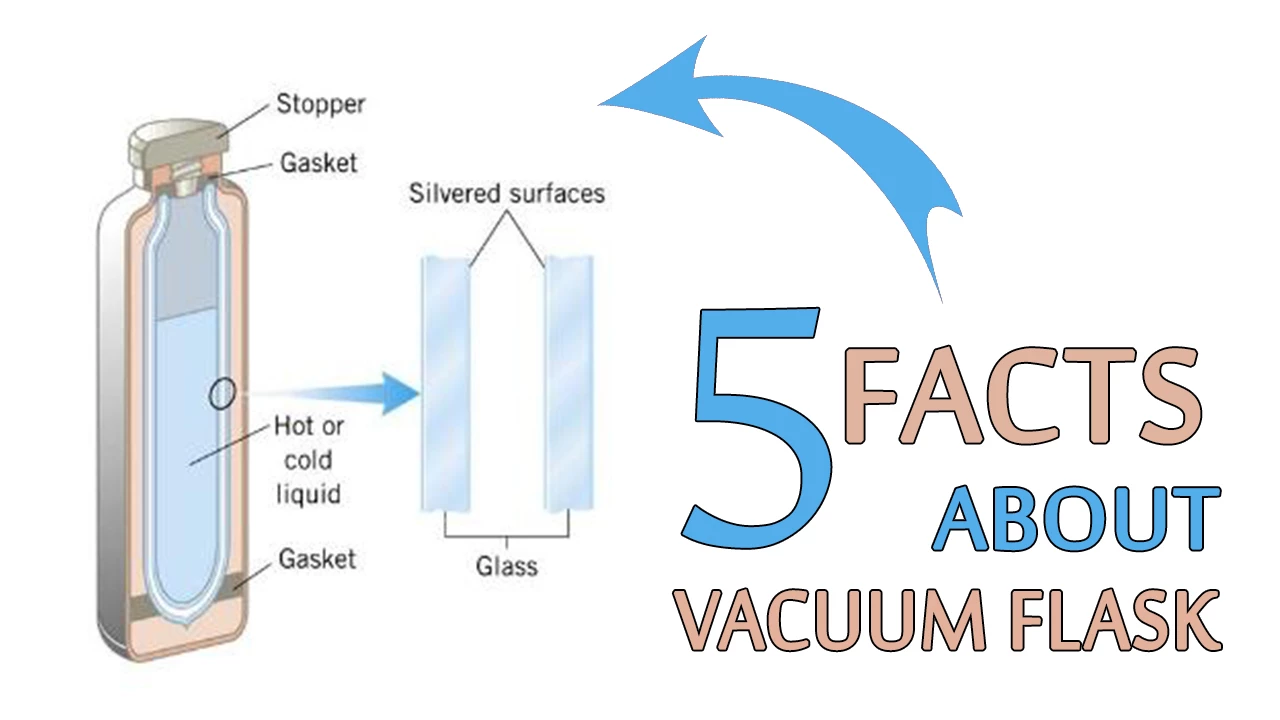

Parts of a vacuum flask

Parts of Rang Dong’s vacuum flask.

Nowadays, vacuum flasks are popular. Each family would own at least one vacuum flask to keep their drinks hot or cold. Normally, a vacuum flask has four main parts, namely glass refill (or glass liner), casing, bottom and gasket. Casing and bottom are made of plastic or stainless steel, the gasket is made of silicone, and the glass refill is made of silver-plated neutral glass.

Although stainless steel bottles are chosen to produce thermos, Rang Dong still selects neutral glass for its vacuum flask thanks to the safe function for food contact and human health. Rang Dong has invested in automatic production lines of glass liner and can control the whole process from input to output stages for making perfect glass liner for customers worldwide. Rang Dong’s glass liner has been exported to many countries and territories, including Brazil, Indonesia, China and the Middle East.

How to produce a glass refill?

Rang Dong is one of the world’s biggest manufacturers of glass refills. The Hanoi-based company has improved its glass furnaces and production lines from time to time, so it is now capable of making perfect glass refills for vacuum flasks.

Firstly, Rang Dong prepares silica material. It must be clean and without iron or any other metals. Workers add sodium hydrogen carbonate (NaHCO3) and calcium oxide (CaO) into silica to raise the water-proof function of the glass. Besides, several other additives can be supplemented to improve glass performance, depending on purpose of usage.

Secondly, the compound would be heated in a glass furnace under about 2,000oC. The result of this stage is neutral glass. Setting up a high temperature for a glass furnace is very important to make a perfect glass. Rang Dong totally masters at this stage.

Thirdly, melting glass is put into molds for shaping. Right after molding, the glass bottle is cooled immediately. Glass bottles will undergo many steps before being silver-plated. One thin layer of silver is coated on a glass bottle surface to help it keep the temperature of the drink inside. The output of this stage is glass refill or glass liner (silver-plated glass bottle).

Glass is formed inside the mold.

Finally, the glass liner will be inspected and tested in Rang Dong’s laboratory to ensure its quality based on the requirements of LFGB and BS EN 12546-1:2000, the popular international standards for food contact materials and food containers. The passed glass liner is transported into stock, waiting for being assembled into the finished vacuum flask.

Rang Dong's glass refill is safe for human health

Rang Dong’s series of glass refills.

Being controlled in an ISO-qualified factory, complied with LFGB and BS EN 12546-1:2000 standards, Rang Dong’s glass refill is totally safe for human health. Moreover, the diversity of shapes and the output volume of glass liner for various finished vacuum flask are among Rang Dong’s strengths. Customers around the world have been convinced and trusted the company’s perfect glass refill.

Should you have any questions, wish to share your ideas about vacuum flasks or request a quotation, please send us an email to: export@rangdong.com.vn.

Our website: vacuumflask.rangdong.com.vn