Vietnam's Rang Dong makes spare glass refills for vacuum flasks

Rang Dong Light Source and Vacuum Flask Joint Stock Company, founded in 1961, was the first in Vietnam's northern region to begin producing vacuum flasks, also known as thermos. Since then, millions of Vietnamese as well as foreign consumers have grown to love the Rang Dong vacuum flask. Aside from designing new styles and shapes for the product, the Hanoi-based company also produces thermos spare parts such as glass refills.

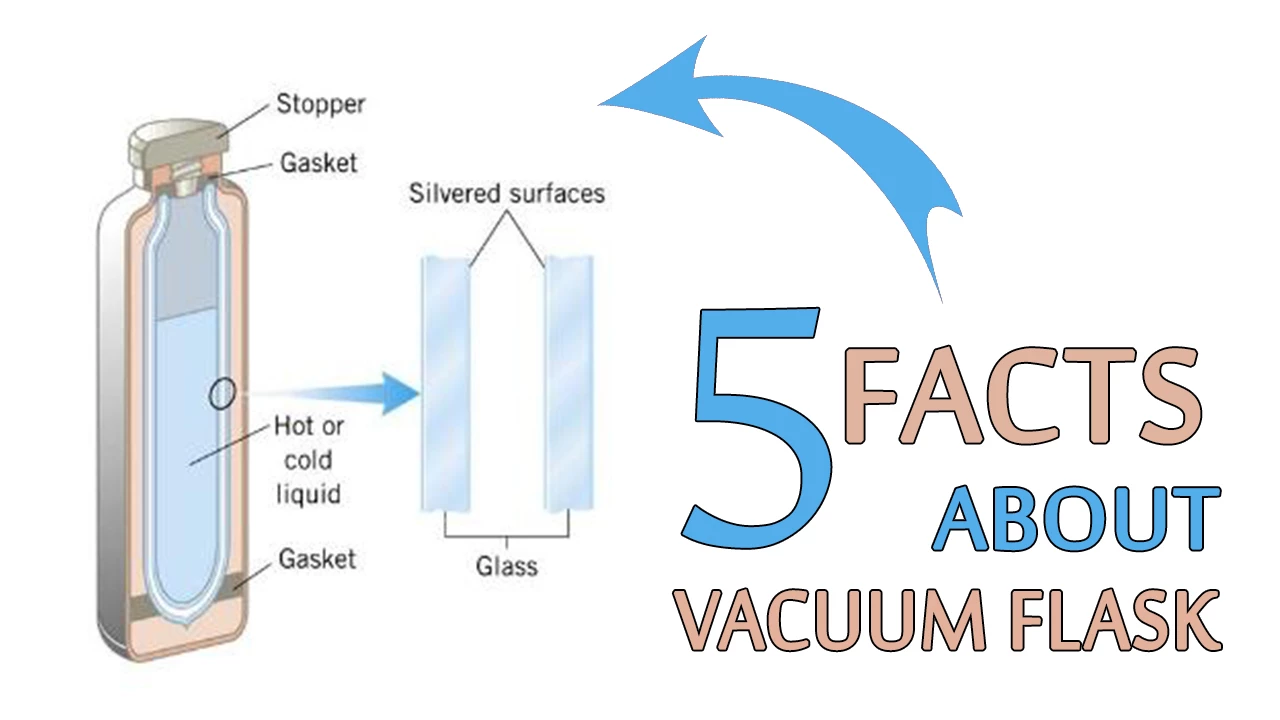

How vacuum flasks work

A vacuum flask is similar to a well-insulated jug. The majority of models have an inner chamber and an outer plastic or metal case, separated by two layers of glass and a vacuum in between. A reflective metal layer is usually applied to the glass.

These few, simple features prevent almost all heat transfer via conduction, convection, or radiation. Conduction is prevented by the vacuum. Since the tight stopper prevents air from entering or leaving the flask, convection is also impossible. When infrared radiation tries to escape the hot liquid, it is reflected back in by the reflective lining of the inner chamber. A vacuum flask allows almost no heat to escape, so a hot drink stored inside will stay steaming hot for several hours.

Flasks can also be used to store cold drinks. If heat cannot escape from a vacuum flask, it also means that heat cannot enter the flask from the outside. The sealed stopper prevents heat from entering by convection, the vacuum prevents conduction, and the metal lining between the outer case and the inner chamber prevents heat from radiating in either direction.

Glass Refill

Most of the raw materials, such as limestone, dolomite and sand are sourced from domestic suppliers in Hai Phong city, Ha Nam province and Van Don of the northern province of Quang Ninh. Other materials are imported from countries such as the United States and China.

Sand is the most important raw material among them. To ensure the quality of the glass, the particle size of the sand used in production must be less than 1.4 millimeters. They will be sieved carefully to remove impurities before being dried to specific moisture content.

Another material is glass fragments. The glass fragment is used in the furnace to lower the temperature inside. If all raw materials are used for melting, the furnace temperature can reach 1,700 degrees Celsius. Despite the fact that the glass fragments melt faster, the furnace temperature only reaches 1,500 degrees Celsius. The use of glass fragments contributes to reducing waste.

Rang Dong, Vietnam’s leading manufacturer of vacuum flask products, uses all these materials to make the glass refill. The thermos part is made up of two glass 'jars' that are placed one inside the other and separated by a layer of vacuum. The company uses two assembly technologies, namely waist sealing and bottom sealing, to create a complete glass refill.

The inner surface of the outer bottle and the outer surface of the inner bottle will then be plated with a nano-silver layer to improve heat radiation. The gas inside the gap between the inner and outer bottles will be sucked and sealed until the pressure inside the gap reaches minus 2 to the tenth Torr. The vacuum inside the gap aids in reducing heat transfer.

Given the multi-layer structure, Rang Dong's glass refill can help retain hot or cold beverages for a long time.

The safest material for food contact is neutral glass. That is why Rang Dong has dedicated a part of the company's manufacturing operation for a line of vacuum flasks to protect customer health.

Should you have any questions or request a quotation of Rang Dong products, please send us an email to: export@rangdong.com.vn.

Websites: en.rangdong.com.vn and vacuumflask.rangdong.com.vn