Rang Dong Company accelerates the digital transformation process

In order to quickly adapt to the new competitive environment and conditions of the globalization and I-4.0 revolution and despite the challenges of the technological layer transformation (from a technological company to a high-tech company), on July 1, 2019, Rang Dong decided to form a new program in focus: Program No. 1: Digital transformation of the Company.

Rang Dong's Digital Transformation Process

In order to quickly adapt to the new competitive environment and conditions of the globalization and I-4.0 revolution and despite the challenges of the technological layer transformation (from a technological company to a high-tech company), on July 1, 2019, the Company decided to form a new program in focus: Program No. 1: Digital transformation of the Company.

On October 5, 2019, the Company presented the first version of a project on digital transformation in the 2020-2025 period to Dr. Nguyen Quan - Chairman of the Vietnam Automation Association, Former Minister of Science and Technology.

Mr. Nguyen Quan - Former Minister of Science and Technology, Chairman of Vietnam Automation Association, highly appreciated Rang Dong's achievements, especially the company's digital transformation path.

In November 2019, the Company was selected by the Ministry of Industry and Trade, Siemen Group and TŨV/SŨD to be among 15 companies for the preliminary assessment of the SIRI readiness index for digital transformation and also picked for further in-depth assessment in the second step.

On October 12, 2019, Rang Dong’s Executive Party Committee issued a Resolution on urgently and seriously implementing the Politburo’s Resolution No. 52 and approving the second version of the project on Digital Transformation of the Company in the 2020-2025 period, vision to 2030.

The main idea of the Company's development strategy is to move from a technology company to a high-tech company, which is digital transformation; Producing digitally integrated products, transforming business models on digital platforms, changing production processes based on digital data - automation - virtualization and e-commerce development - Building production factories Rang Dong's production in the direction of "Make in Vietnam": Created in Vietnam, Designed in Vietnam and Made in Vietnam.

Automatic assembly line researched, designed and manufactured by Rang Dong engineers.

Because of achieving the goals of the 2nd renovation, Phase 2 before one year. Rang Dong’s Party Committee has decided for the company to begin Phase 2 of the 2nd Renovation in 2020, with the basic target on “Digital transformation of the Company in the 2020-2025 period, vision to 2030.” Starting from 2020, a new idea creation center was established to gather outstanding individuals.

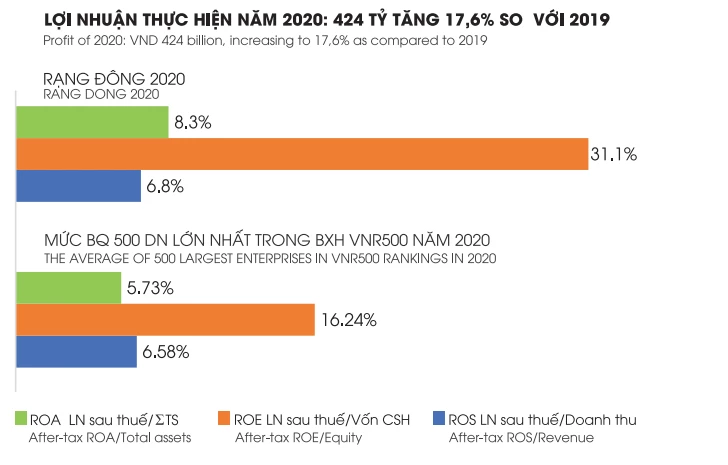

The indicators ROA, ROE and ROS of Rang Dong have grown over the years, showing the company's sustainable development and affirming its high value stocks in the securities market.

In 2020 Rang Dong's ROA reaches 8.3%. 1.46 times higher than the average of 500 largest enterprises in Vietnam. This is a positive sign, showing the company's current effective assets management.

Rang Dong's ROE reaches 31.1%, 1.92 times higher than the average of 500 largest enterprises in Vietnam, showing the company's effective capital usage and affirming its sustainable competitive advantage, technological and production size advantage, accordingly, the cost of goods sold/product is lower. In addition, enterprises with strong brands will have the right to set a higher price level than other competitors.

Rang Dong's ROS reaches 6.8% and is 3.76% higher than the average of 500 largest enterprises in Vietnam, affirming the company's good operation, good expenditure control, high profit and sustainable development. A company that wants to sustainably develop must keep its ROS indicator steady or increasing over time. It means that it would be very good if this indicator is always kept stable or increases for 3 to 5 years.

Digital transformation in Vacuum Flask & Glass Factory

Completion of SCADA System in charge of controlling glass production and automatically updating and acquiring the data of glass refill production.

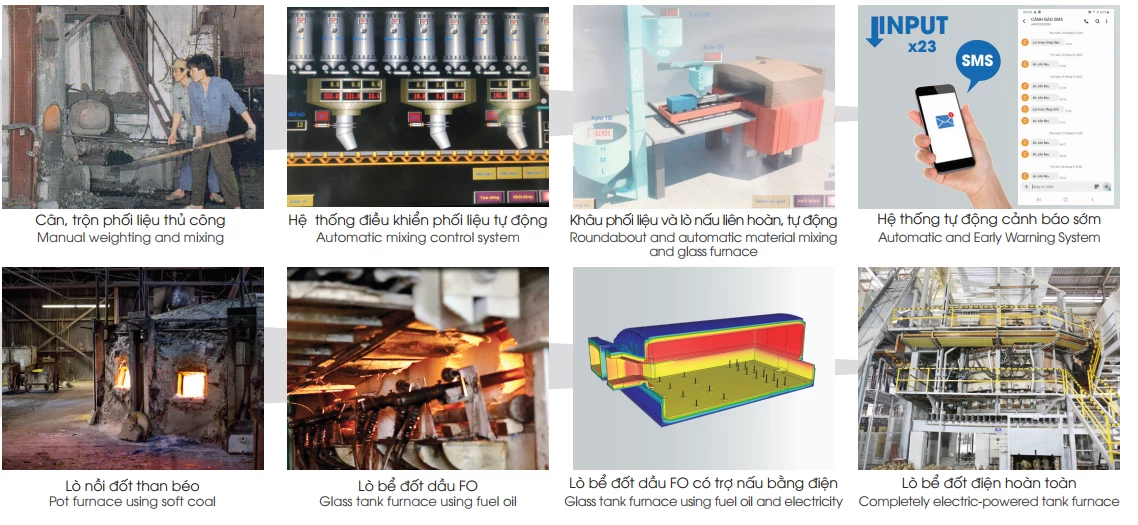

Material mixing, glass cooking, glass refill blowing and vacuum flask production from manual method to modern technologies.

Transformation of 4 Technological Layers

In its 60-year history, Rang Dong Company has undergone 4 stages of technological transition, from filament lamp technology based on the Joule effect of electric current, to discharge lamp technology based on the principle of collision. mercury atoms into the excited state and solid lighting technology layer (SSL-LED) and new technology layer: LED Ecosystem 4.0.

Every time the technology layer transitions, there is often a star change phenomenon. But in Rang Dong, each technology transition is a time to strengthen the leading position of Rang Dong brand in Vietnam's lighting industry. Developing by kindness, by Science - Technology is a successful lesson of Rang Dong that the Creative Labor movement must consider as the cross-cutting goal of all topics.

With the advancement of LED chips since the 2014 Nobel Prize until now, leading corporations such as SamSung, Seoul Semiconductor (SSC) which are strategic partners of Rang Dong have developed a type with high luminous efficiency of 220-250 Lm/W, which has a light spectrum and CRI close to natural light, has monochromatic and UV spectral types.

Adopting the latest achievements of physics, biology and digital technology, bringing high technology into products, design, manufacturing and management capabilities to create LED Ecosystem 4.0 including categories: CSL, HCL, HTAL and developing lighting systems in medical and optical instruments that bring new values to customers in terms of energy saving, joining Smart Home Ecosystem, Smart City is the way increase the proportion of high-tech products from 20 percents to 80 percents in the coming years.

Customers experience products from online showroom with AR virtual reality space.

Rang Dong's core product in this period is "LED Ecosystem 4.0" which is a package synchronization service, which is a product and service with a high level of complexity: In order to implement that Product Strategy, it must be enhanced. R&D capacity, design capacity, production capacity and management are digitized. To sell those products and services requires quickly developing a new business model on digital platforms with different consumer behavior and roles from the traditional market.

Electronic component assembly capacity 350 million components/month.

Being sensitive and proactive in embracing the I-4.0 Revolution, since 2017 Rang Dong Company has developed Smart LED products; connecting, connecting, digitizing and implementing ISO - Online in a number of lines; Implement ERP application software in a factory, in order to approach and test Digital Transformation.

Should you have any questions, wish to share your ideas of vacuum flask, or request a quotation, please send us an email: to export@rangdong.com.vn.

Our website: vacuumflask.rangdong.com.vn.