Rang Dong turns glass refill production modern, eco-friendly

The process of glass refill production is pivotal as it helps determine high-quality vacuum flasks. Rang Dong has combined traditional methods with modern technology to ensure product safety and environmental sustainability. Let's explore the intricacies of the company's glass refill production.

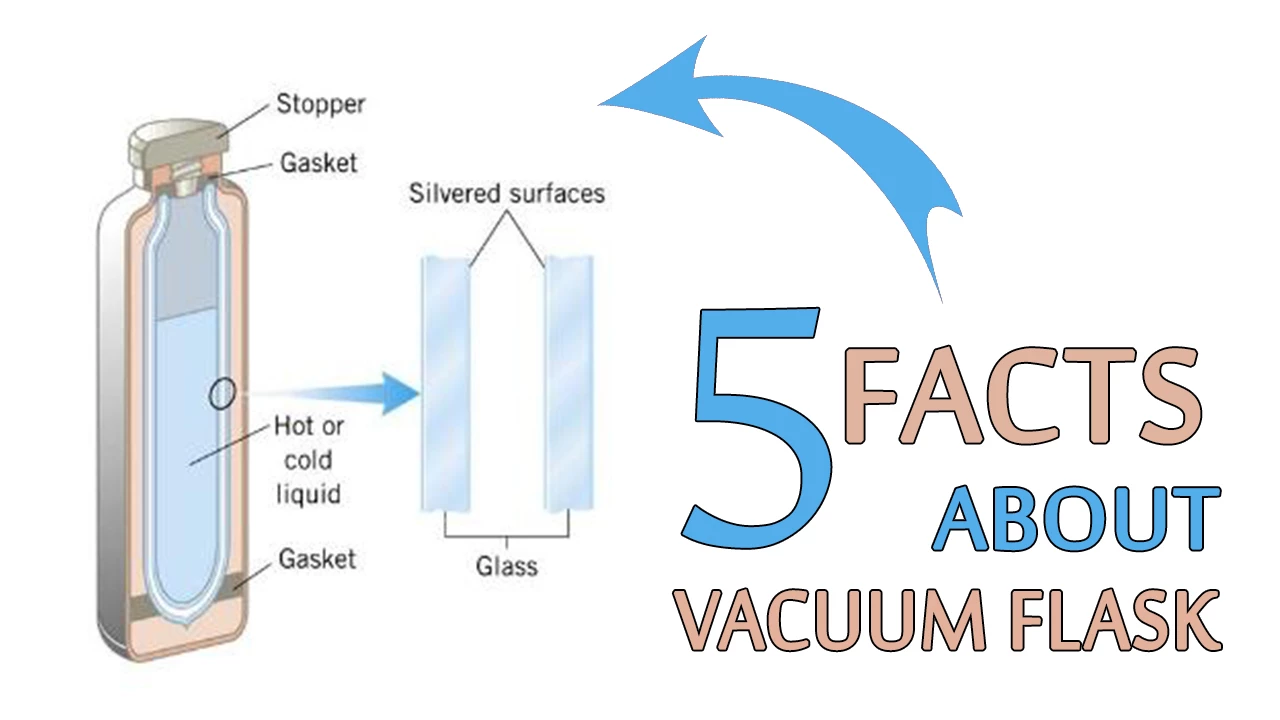

Vacuum flasks were developed in the late 19th century and have gained widespread popularity since the early 20th century. Today, billions of consumers globally use these products to maintain the temperature and purity of their beverages.

Vietnam's Rang Dong is proud to stand among leading manufacturers of vacuum flasks, exporting products across continents from Asia to Europe to South America.

Rang Dong's Production

The Hanoi-based company has structured vacuum flask production in four main phases: glass refill production, glass refill assembly, casing production, and final assembly of the vacuum flask.

Stage 1: Glass Refill Production

This critical phase begins with the careful selection and filtration of raw materials like sand, soda, and limestone, which are then melted in a furnace. The furnace temperature is kept at a minimum of 1,000 degrees Celsius to ensure the glass's consistency and clarity.

Unlike older methods where workers manually blew into glass to shape it, Rang Dong now utilizes automated glass-blowing machines to enhance efficiency.

The glass is subsequently molded into various sizes and designs, with capacity ranging from one liter to 3.2 liters.

A Rang Dong worker carefully examines sand before moving it to the glass furnace.

Stage 2: Glass Refill Assembly

At this stage, the glass is cleaned, cut, and silver-plated. Additional steps include asbestos application, bottom sealing, bottle heating, vacuum application, body attachment, and testing.

The key processes determining the insulation quality are the bottom sealing, body attachment, and silver plating. Rang Dong focuses to make sure that the glass liners comply fully with food safety standards.

Bottom sealing is among the three most challenging steps in production, playing a crucial role in determining how long the heat is retained.

Stage 3: Casing Fabrication

Casings are made from either plastic or stainless steel, each through a specialized process. For plastic casings, a combination of mixers and compressors is used to mold Polypropylene (PP) and Acrylonitrile Butadiene Styrene (ABS), which meet both national and international food safety standards.

Stainless steel casings require intricate procedures like cutting, rolling, and bending, conducted by skilled workers to ensure precision and quality.

Stage 4: Final Assembly of the Vacuum Flask

In this final step, all components including the glass bottle, casing, and accessories like labels and nylon bags are assembled manually. This stage focuses on meticulous quality checks and packaging, ensuring the product’s durability, while the appearance should meet high standards.

Throughout the process, Rang Dong adheres to stringent ISO standards for quality, environmental, and energy management, as well as food safety regulations. Rang Dong's commitment to quality and safety helps make its vacuum flasks a trusted choice for consumers worldwide.

Should you have any questions or request a quotation of Rang Dong products, please send us an email to: export@rangdong.com.vn.

Websites: en.rangdong.com.vn and vacuumflask.rangdong.com.vn