Glass refill making ensures thermos flask manufacturer's success

The liner inside a flask - an indispensable item for many of us - can be made from stainless steel or glass, while production of the latter item now exists only in several countries, including China, India and Vietnam. We will be looking at the process of making glass refills to determine what makes it a quality item.

Glass refill making process

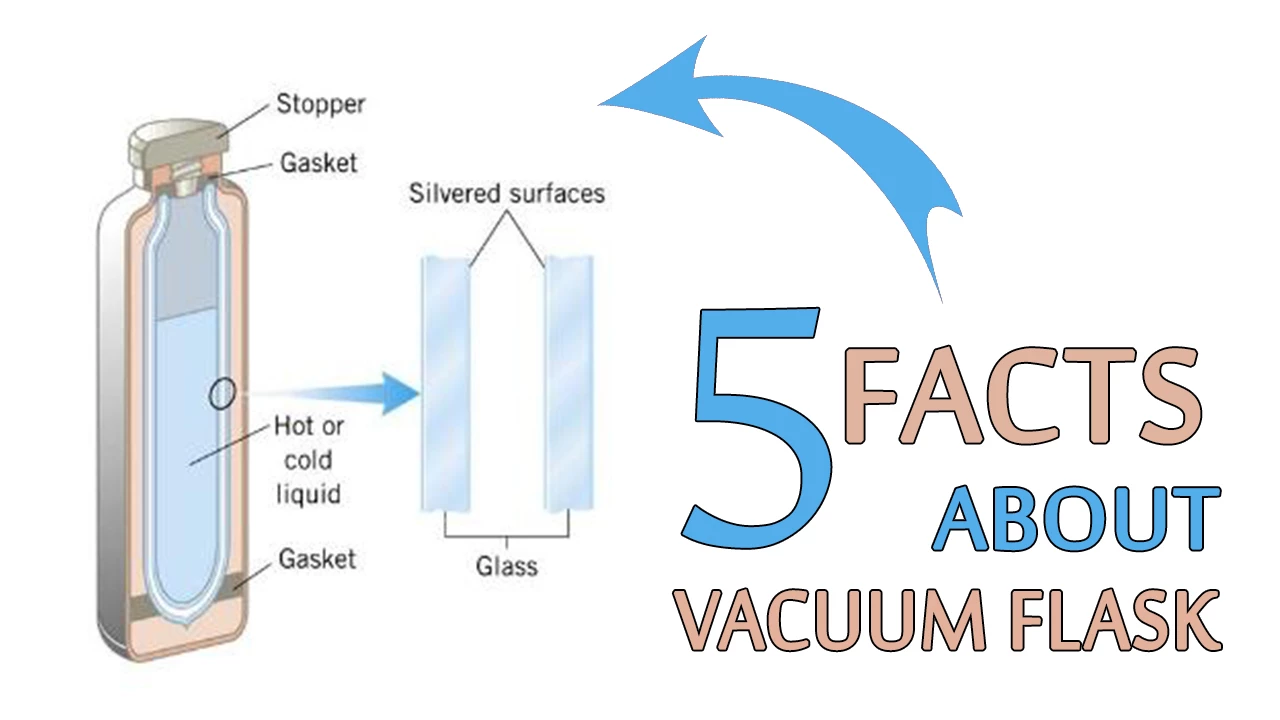

From the outer surface, a completed glass refill consists of five layers, namely an outer bottle, a silver-plated layer on the inner surface of the outer bottle, a vacuum gap, a silver-plated layer on the outer surface of the inner bottle and an inner bottle.

Firstly, raw materials including limestone, dolomite, sand and glass fragments are sieved and mixed firmly. The mixture is then moved into a glass furnace and melted under 1,700 degrees Celsius. Next the 'liquid' is fed into molds to form glass bottles.

A glass furnace inside a thermos flask manufacturer’s facility

Next, the bottoms of the outer bottles are cut open to allow workers to insert inner bottles. After that the outer bottles are sealed, using either the waist sealing technology or the bottom sealing technology.

After that, the outer surface of the inner bottles and the inner surface of the outer bottles will be plated with a nano-silver layer to increase heat radiation. In the next stage, the air in the gap between the inner bottle and the outer bottle will be sucked out to help prevent heat transfer until the pressure inside reaches 10-2 Torr. The bottom pipe will then be sealed.

The surface of a glass bottle is covered by a silver-plated layer

The difference between bottom sealing method and waist sealing method

As mentioned above, two methods, namely bottom sealing or waist sealing, could be used to seal the bottom of the outer bottle.

While both of them use heat for melting, the bottom sealing method melts the bottom, then pulls it and twists to seal it. The waist sealing method uses heat to melt the edge of the outer bottle body and that of an extra part of the outer bottle, then attaches them.

The other difference of the technologies is that the bottom sealing method can be applied on just one shape of glass refill, while the waist sealing method can be used for various shapes and volumes.

The quality of glass refill

A good glass refill can be evaluated based on the following criteria.

i) The transparency of the neutral glass: This feature is formed thanks to the glass melting stage. The quality of the neutral glass used for inner and outer bottles depends closely on how raw materials are mixed and the furnace controlled.

ii) The heat radiation of the silver-plated layer: This layer shall be evenly and adhesive stuck to the surfaces of the inner and outer bottles. This is decided by the content of the silver nitrite solvent and the spin speed to extract silver particles;

iii) The pressure inside the gap between the inner and outer bottles: The pressure shall be at 10-2 Torr while higher or lower values won't guarantee the optimal heat transfer.

Thanks to the multi-layer structure and the safety of neutral glass, the glass refill can keep hot and cold for a long time. A thermos flask manufacturer can make glass refills with all the criteria of a prestige brand.

Glass refills can come in different shapes and sizes, depending on the design of the thermos flask manufacturer

Should you have any questions, wish to share your ideas of flasks, or request a quotation, please send us an email to: export@rangdong.com.vn

Our website: https://en.rangdong.com.vn/